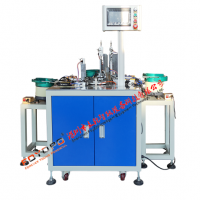

Equipment Introduction: Cold Heading Machine

1. This equipment is a customized model mainly used for automobile tie rod extrusion molding.

2. This device is a general-purpose device.

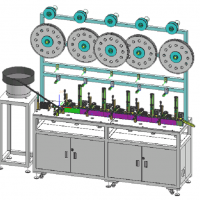

3. This equipment is fully automated for production. The vibration plate is automatically loaded, the robot automatically loads, forms and unloads. The human hand only needs to pour the processed product into the vibration plate. It is convenient and fast, and one person can operate multiple devices at the same time.

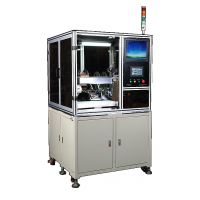

4. Equipped with a programmable controller (PLC), the mechanical actions are all designed by software and tested by computer to ensure that each action is reasonable and conflict-free. The equipment control interface is a full touch human-machine interface, which can be operated according to the prompts on the interface. It is simple and clear, and novices can also operate it skillfully. The equipment has automatic counting and automatic alarm functions, which is convenient for operators to calculate production and troubleshoot faults.

Application areas:

Auto parts cold heading machine is used in automobile, hardware and electronic parts industries: automobile tie rods, automobile brake plate tie rods, other automobile parts, door and window hinges and latches, electronic precision parts, etc.

Technical Parameters:

Device Name | Auto parts cold heading machine |

model | YL-QC160420 |

power | 7KW |

Voltage | 380V/50Hz |

Air pressure | 0.4-0.7MPA |

Equipment capacity | 35PCS/MIN |

Features | Multiple general use |

Total weight of unit | 800kg |

Overall dimensions (length x width x height) | 1600×900×1400mm |