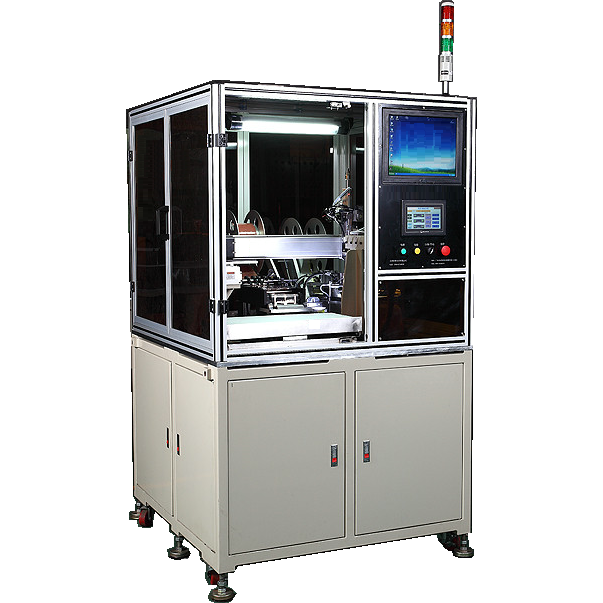

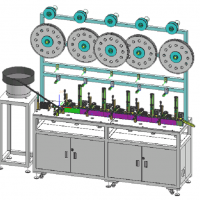

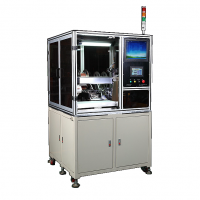

Equipment Introduction:

1. The inspection and labeling machine is fully automated. Manually place the material tray into the equipment, and the equipment will automatically detect the appearance, size, label and distinguish defective products. You only need to fix the material tray in the equipment, which is convenient and fast. One person can operate multiple devices at the same time.

2. This device is a general-purpose device.

3. Equipped with a programmable controller (PLC) , all mechanical actions are designed by software and tested by computer to ensure that each action is reasonable and conflict-free. The equipment control interface is a full touch human-machine interface, which can be operated according to the prompts on the interface. It is simple and clear, and novices can also operate it skillfully. The equipment has automatic counting and automatic alarm functions, which is convenient for operators to calculate production and troubleshoot faults.

Application areas:

Electronic product CCD inspection and labeling machine is used in the electronics industry: inspection and labeling of electronic components, electrical appliances, and electrical accessories, etc.

Technical Parameters:

product name | CCD detection labeling machine |

model | YL-CCD160804 |

power | 1.5KW |

Voltage | 220V/50Hz |

Air pressure | 0.4-0.7MPA |

Equipment capacity | 110PCS/MIN |

Features | Multiple universal |

Total weight of unit | 900kg |

Overall dimensions (length x width x height) | 1400×1200×1300mm |