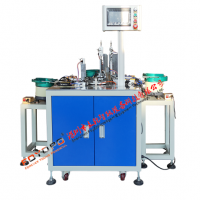

Equipment Introduction: Automatic assembly inspection machine

1. This equipment solves the traditional manual assembly, effectively reduces labor costs, and has functions such as automatic loading, automatic assembly, and automatic testing, realizing truly unmanned automatic production.

2. This device is a single general-purpose device.

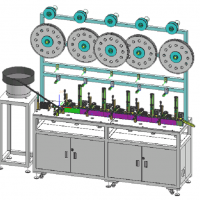

3. This equipment is a fully automated equipment, with automatic loading of the vibration plate and the robot, automatic assembly, automatic detection, and automatic unloading. The human hand only needs to pour the processed products into the vibration plate, which is convenient and fast.

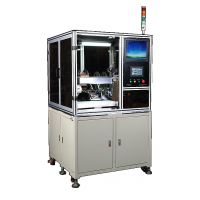

4. Equipped with a programmable controller (PLC) , all mechanical actions are designed by software and tested by computer to ensure that each action is reasonable and conflict-free. The equipment control interface is a full touch human-machine interface, which can be operated according to the prompts on the interface. It is simple and clear, and novices can also operate it skillfully. The equipment has automatic counting and automatic alarm functions, which is convenient for operators to calculate production and troubleshoot faults.

Application areas:

JACK power connector automatic assembly and testing machine is used in the electronics industry: power plugs, computer peripheral connectors, etc.

Technical Parameters:

product name | JACK power connector automatic assembly inspection machine |

model | YL-DZ160720 |

power | 3.5KW |

Voltage | 220V/50Hz |

Air pressure | 0.4-0.7MPA |

Equipment capacity | 30PCS/MIN |

Features | Single universal |

Total weight of unit | 1500kg |

Overall dimensions (length x width x height) | 2600×1100×1300mm |