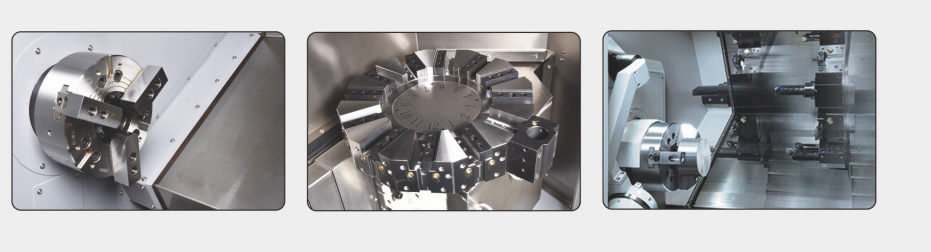

Product name: Shenzhen slant bed CNC lathe

Model: CNC-500T

Product introduction: The slant bed CNC lathe is a high-precision and high-efficiency automated machine tool. Equipped with a multi-station turret or a power turret, the machine tool has a wide range of process performance and can process linear cylinders, oblique cylinders, arcs and various complex workpieces such as threads, grooves, and worms. It has various compensation functions for linear interpolation and circular interpolation, and has played a good economic effect in the mass production of complex parts. The plane where the two guide rails of the slant bed CNC lathe are located intersects with the ground plane to form an inclined plane with angles of 30°, 45°, 60°, and 75°. The bed of the slant bed CNC lathe is a right triangle. Obviously, under the same guide rail width, the X-direction slide of the slant bed is longer than that of the flat bed. The practical significance of its application in the lathe is that more tool positions can be arranged. The cross-sectional area of the slant bed CNC lathe is larger than that of the same specification flat bed, that is, it has stronger anti-bending and anti-torsion capabilities.

Advantages of slant bed CNC lathe:

Good stability

When processing oversized parts, inclined bed or flat bed inclined guide machine tools are generally used. Because the corresponding components of medium and large machine tools are also large, especially the turret part, the inclined guide rails are mainly used to overcome gravity and have better stability to improve the accuracy of the machine tool. The superiority of inclined bed machine tools can be reflected in some harsh environments.

Improve space utilization

The inclined machine tool can effectively utilize the space and greatly reduce the plane space occupied by the machine tool.

Easy to remove chips

The inclined guide rail also makes it easier to concentrate the iron chips on the chip conveyor for automatic chip removal. The iron chips from cutting carry high heat, which will accumulate on the guide rail and cause the guide rail to deform due to heat, causing changes in working accuracy, and in the process of batch automatic processing, it will lead to the scrapping of batches of workpieces.