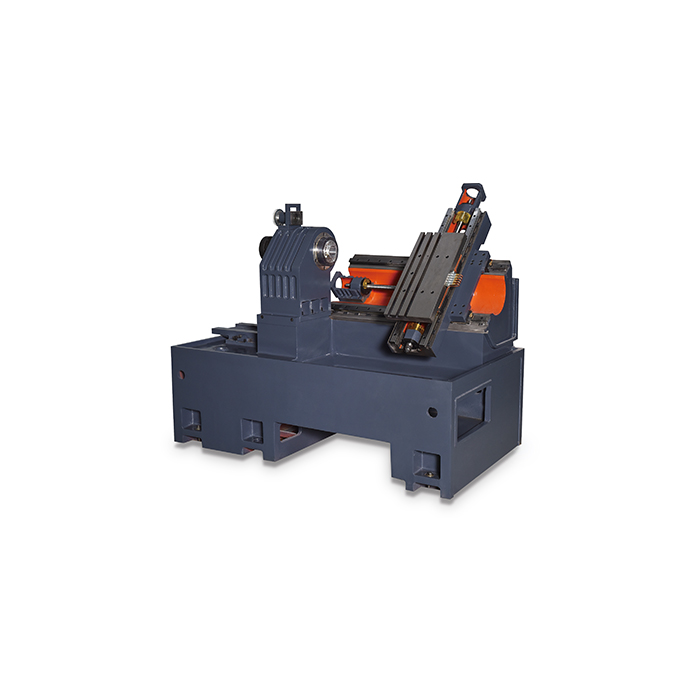

Product Name: Optical Machine

Product introduction: Optical machines are low-end products of CNC machine tools. Compared with the core components of machine tools such as CNC systems, they have lower technical content. However, this does not mean that optical machines are very easy to manufacture. The design and manufacturing process level of optical machines are directly related to the quality, life and reliability of CNC machine tools, requiring production enterprises to have a high level of technology and management. While improving product quality and level, my country's optical machine manufacturing enterprises also need to take the path of independent innovation, develop core components of CNC machine tools, and improve the production level and economic benefits of enterprises.

Stable and super strong structural castings:

1. Use advanced finite element analysis to simulate the pressure distribution of the structure with a computer, analyze the design changes and structural position and other important mechanical and physical change factors, and conduct tests and analyses to ensure that the design of each mechanical part is improved to the best condition.

2. The main machine components are integrated into a strong foundation. The low-center-of-gravity machine tool 30/45-degree saddle design provides an extremely stable base for the machine head, turret and tailstock.

3. Both axes are supported by full linear rails, which can achieve fast and efficient processing. The wide space inside the machine allows the operator to easily replace the tool and the clamping jaws, and with the high-rigidity structure, a multifunctional and high-stability machine tool with high speed, high precision and high finish is created.

Pre-stretched ball screw:

Dongquan only uses high-precision ball screws produced by world-renowned brand manufacturers. Although the price is more expensive, the excellent quality is a way to meet the high precision and long life required by customers. The screw is fixed at both ends and tested to ensure that it is 100% parallel to the linear rail. The pre-tensioned ball screw can effectively eliminate the thermal extension caused by temperature rise.

Direct-coupled servo motor:

After the motor seat is corrected by scraping at both ends, the motor mounting surface will not be at a 90° angle to the screw shaft, so our company uses additional surfaces for balance correction. The servo motor is directly connected to the ball screw through a coupling, and the screw will not deform or misalign even under heavy loads. This will greatly improve positioning accuracy and make thread and shape processing more accurate. These couplings will not wear or reduce accuracy after long-term use .