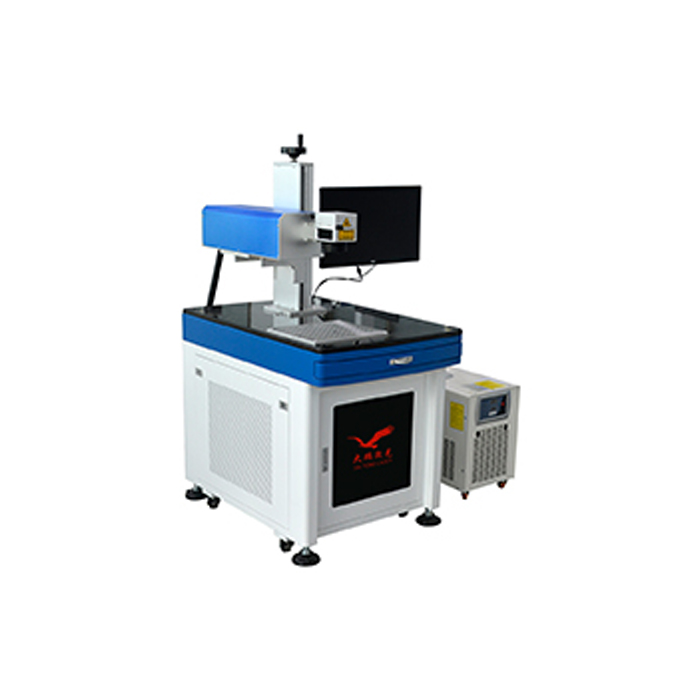

Product name: UV laser marking machine

Laser marking machine is developed with ultraviolet laser of wavelength 355nm, adopts third-order intracavity frequency doubling technology, and integrates international advanced technology. High-energy ultraviolet photons directly destroy the molecular bonds on the surface of many non-metallic materials, making the molecules separate from the objects. This method does not generate high heat. The ultraviolet laser has a very small focused spot and the processing has almost no thermal impact, so it is called cold processing, which is suitable for ultra-fine marking and engraving of special materials.

Features:

Dapeng series products incorporate internationally advanced technology. High-energy ultraviolet photons directly destroy the molecular bonds on the surface of many non-metallic materials, causing the molecules to separate from the object. This method does not generate high heat. The ultraviolet laser spot is extremely small, and the processing has almost no thermal impact, so it is called cold processing. It is suitable for ultra-fine marking and engraving of special materials.

Application areas:

The concentrated spot of ultraviolet laser is very small, and the processing has almost no heat effect, so it is called cold processing, and is therefore suitable for ultra-fine marking and engraving of special materials. It is mainly used in the high-end market of ultra-fine processing, surface marking of packaging bottles of cosmetics, medicines, foods and other polymer materials; marking and scribing of flexible PCB boards; micro-hole and blind hole processing of silicon wafers; QR code marking of LCD glass, marking of glassware, removal of metal surface coating, plastic buttons, electronic components, communication equipment, etc.

Product advantages:

Ultraviolet laser has short wavelength and smaller focused spot, which can realize ultra-fine marking. It is cold processing, with small heat-affected zone, which can avoid damage to the processed materials and has high yield rate. It is applicable to a wide range of materials, which makes up for the lack of infrared laser processing capability. It uses high-speed digital galvanometer, which has fast marking speed, high efficiency and high precision. It does not require consumables, and has low use cost and maintenance cost. The whole machine has stable performance and can run for a long time.