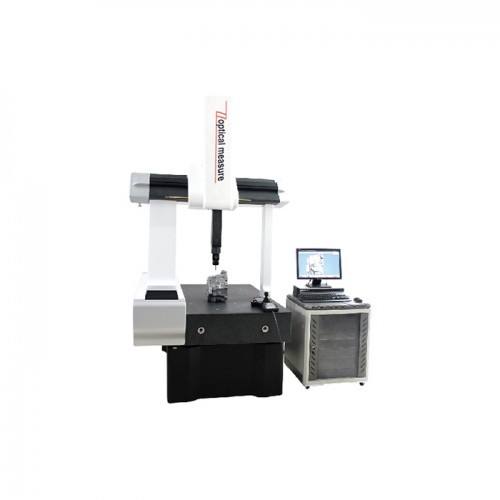

2.5-dimensional measuring instrument image probe composite instrument VMT series

Technical parameters:

1 | Instrument Model | VMT300 | VMT400 | VMT500 |

2 | Main body outer dimensions (mm) | 1300*850*1650 | 1500*950*1650 | 1700*1100*1650 |

3 | Optical glass table size (mm) | 339*239 | 439*339 | 539*439 |

4 | Actual effective range (mm) | X-axis: 400 / Y-axis: 300 | X-axis: 400 / Y-axis: 300 | X-axis: 500 / Y-axis: 400 |

5 | Instrument weight (KG) | 220 | 280 | 360 |

6 | Instrument load-bearing capacity (KG) | 30 | ||

7 | Instrument material | 00-grade marble base, columns, and work surfaces are durable, beautiful, and will not deform. | ||

8 | CCD Camera | American TEO high-definition color CCD | ||

9 | Lens | step zoom lens, optical magnification 0.7X~4.5X, image magnification: 28X-180X | ||

10 | Grating scale resolution | 1um (0.5um optional) | ||

11 | X, Y axis accuracy (um) | 3+L/200 | ||

12 | Transmission mode | Three-axis manual, V-guide combined with threadless screw drive | ||

13 | Surface lighting | High brightness LED adjustable ring cold light source | ||

14 | Contour lighting | LED circular cold light source with adjustable brightness | ||

15 | Calculation measurement function | Precision measurement system software | ||

16 | Usage Environment | Power supply: AC 220V 50/602HZ Temperature 22±5℃ Humidity 45%-75% | ||

17 | Warranty | 12 months | ||

2.5 Dimensional Measuring Instrument Product Features:

● Measurement software for processing and output; powerful and comprehensive functions; measurement can be manually programmed.

● The whole machine adopts high-precision marble structure, which will never deform, has high stability and looks elegant and beautiful.

● Precision-grade guide rails; extremely high stability.

● It is suitable for a wide variety of products with complex sizes and high precision requirements. Its effect is more convenient and quick, and it improves the efficiency of detection and measurement.

● Adopting precision toothless smooth rod transmission, it can make fine adjustments and move quickly, which improves the measurement efficiency.

● The advantages of the instrument's image processing function include: automatic removal of burrs and rough edges, automatic generation of measurement reports, statistical analysis of test results, and the ability to connect to a printer, etc., making it suitable for a wide range of industries.

Application areas:

Widely used in machinery, electronics, molds, plastics, die cutting, precision hardware, precision stamping, connectors, connectors, terminals, mobile phones, home appliances, computers, LCD TVs, circuit boards (PCB), automobiles, watches, etc.