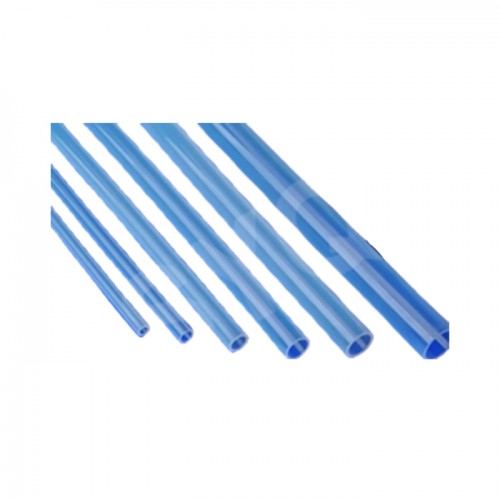

SYQ-PFA is the abbreviation of Polyfluoroalkoxy in English, and its Chinese name is soluble polytetrafluoroethylene. PFA plastic is a copolymer of a small amount of perfluoropropyl perfluorovinyl ether and polytetrafluoroethylene.

characteristic:

High and low temperature resistance: -196--260℃. Non-sticky, water-proof, oil-proof: no fouling inside and outside the tube wall, no stagnation of electrical reliability, high insulation 60HZ-60MHZ high and low temperature dielectric constant viscosity is 2.1. Even if the surface is damaged by diving, no conductive track will be generated, volume resistance>1018ΩM, surface resistance>2*1013ΩM, arc resistance>165 seconds without leakage. Strong corrosion resistance, only elemental fluorine and alkali metals react with it at high temperature, and have no effect on all other concentrated and dilute inorganic and organic acids, alkalis, and esters. Low water absorption: low absorption rate <0.01%, non-flammable: will not burn in the air. (Oxygen index>95VOL.%). Non-toxic: physiologically inert. High transparency: the light refractive index among all plastics. Weather resistance: can be exposed to ozone for a long time, easy secondary processing under sunlight: can be self-sealed, self-welded, flanging, and can be made into coils.

use:

Heat exchangers, steam piping, semiconductors, various frequency wire and cable sheaths, slot insulation pipes; various corrosive media (harsh solvents) delivery pipelines; liquid crystal manufacturing equipment; high-purity reagent delivery pipes; slot insulation pipes for oil-replacing motors; pipes for single-ended luminous single-core optical fibers; pipes for air-conditioning harness assemblies.

Specifications:

Serial number | Inner diameter (mm) | Inner diameter tolerance (mm) | Wall thickness range (adjustable )(mm) | Packing (meter) | Inner diameter (mm) | Inner diameter tolerance (mm) | Wall thickness range (adjustable) (mm) | Packing (meter) |

1 | 0.50 | 0.50±0.10 | 0.05~2.00 | Meter/Strip/Roll | 11.0 | 11.0±0.50 | 0.50~5.0 | Meter/Strip/Roll |

2 | 1.00 | 1.00±0.10 | 0.05~2.0 | Meter/Strip/Roll | 12.0 | 12.0±0.50 | 0.50~5.0 | Meter/Strip/Roll |

3 | 1.35 | 1.35±0.10 | 0.08~2.0 | Meter/Strip/Roll | 13.0 | 13.0±1.00 | 0.50~5.0 | Meter/Strip/Roll |

4 | 1.50 | 1.50±0.10 | 0.08~2.0 | Meter/Strip/Roll | 14.0 | 14.0±1.0 | 0.50~5.0 | Meter/Strip/Roll |

5 | 1.60 | 1.60±0.20 | 0.08~2.0 | Meter/Strip/Roll | 15.0 | 15.0±1.0 | 0.50~5.0 | Meter/Strip/Roll |

6 | 1.70 | 1.70±0.20 | 0.08~2.0 | Meter/Strip/Roll | 16.0 | 16.0±1.0 | 0.50~5.0 | Meter/Strip/Roll |

7 | 2.00 | 2.00±0.20 | 0.10~3.0 | Meter/Strip/Roll | 18.0 | 18.0±1.0 | 0.50~5.0 | Meter/Strip/Roll |

8 | 2.30 | 2.30±0.20 | 0.10~3.0 | Meter/Strip/Roll | 20.0 | 20.0±2.0 | 1.0~5.0 | Meter/Strip/Roll |

9 | 2.40 | 2.40±0.20 | 0.10~3.0 | Meter/Strip/Roll | 25.0 | 25.0±2.0 | 1.0~5.0 | Meter/piece |

10 | 2.50 | 2.50±0.20 | 0.10~3.0 | Meter/Strip/Roll | 30.0 | 30.0±3.0 | 1.0~6.0 | Meter/piece |

11 | 3.00 | 3.0±0.20 | 0.10~3.0 | Meter/Strip/Roll | 40.0 | 40.0±3.0 | 1.0~6.0 | Meter/piece |

12 | 3.50 | 3.50±0.20 | 0.10~3.0 | Meter/Strip/Roll | 45.0 | 45.0±3.0 | 1.0~6.0 | Meter/piece |

13 | 4.00 | 4.00±0.20 | 0.10~3.0 | Meter/Strip/Roll | 50.0 | 50.0±3.0 | 1.0~6.0 | Meter/piece |

14 | 4.50 | 4.50±0.20 | 0.15~3.0 | Meter/Strip/Roll | 60.0 | 60.0±5.00 | 1.5~8.0 | Meter/piece |

15 | 5.00 | 5.00±0.20 | 0.15~4.0 | Meter/Strip/Roll | 70.0 | 70.0±5.0 | 1.5~8.0 | Meter/piece |

16 | 5.50 | 5.5±0.20 | 0.20~4.0 | Meter/Strip/Roll | 80.0 | 80.0±5.0 | 1.5~8.0 | Meter/piece |

17 | 6.00 | 6.0±0.30 | 0.20~4.0 | Meter/Strip/Roll | 90.0 | 90.0±5.0 | 2.0~10.0 | Meter/piece |

18 | 6.50 | 6.5±0.50 | 0.20~4.0 | Meter/Strip/Roll | 100.0 | 100.0±5.0 | 2.0~10.0 | Meter/piece |

19 | 7.0 | 7.00±0.50 | 0.20~4.0 | Meter/Strip/Roll | 120.0 | 120.0±5.0 | 2.0~15.0 | Meter/piece |

20 | 8.0 | 8.0±0.50 | 0.20~4.0 | Meter/Strip/Roll | 150.0 | 150.0±5.0 | 2.0~10.0 | Meter/piece |

twenty one | 9.0 | 9.00±0.50 | 0.50~4.0 | Meter/Strip/Roll | 250.0 | 200.0±10.0 | 3.0±15.0 | Meter/piece |

twenty two | 10.0 | 10.0±0.50 | 0.50~4.0 | Meter/Strip/Roll | 300.0 | 300.0±10.0 | 3.0±15.0 | Meter/piece |

The above are metric size standards (non-standard specifications can be customized according to customer requirements, and the maximum size can be 600mm)

* Color: Transparent, Black; Special colors and packaging can be customized.