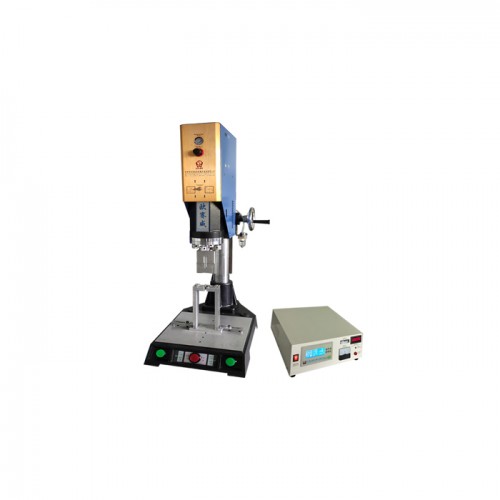

Automatic turntable high frequency heat sealing machine (with robot) is also known as automatic turntable high frequency machine , automatic turntable high frequency heat sealing machine , high frequency automatic turntable welding machine, automatic high frequency plastic welding machine. This machine can automatically rotate the mold plate and perform multi-station heat sealing and welding packaging. It is an upgraded version of the manual turntable high frequency machine.

3 to 6 station automatic turntable high frequency heat sealing machine is more suitable for heat sealing of blister shells, heat sealing and welding of blister shells and paper cards, as well as embossing of PVC or artificial leather, PVC high frequency blister sealing packaging, blister and paper card welding packaging of various electronic, hardware, toys, craft gifts and other products.

The high-frequency automatic turntable welding machine has multiple stations and automatically rotates the mold with precise positioning. It is suitable for large-scale assembly line production. Both the machine and the mold can be customized. The old manufacturer Osaiwei designs, develops and produces high-frequency series and ultrasonic series equipment. It has fast after-sales service, excellent price, high quality, and no worries after sales!

Device Name:

Automatic turntable high frequency heat sealing machine

use:

The automatic turntable high-frequency heat sealing machine is used for heat sealing and welding between PVC/PET plastic blister packaging boxes and paper cards, and can also heat seal and weld leather, PVC sponge sandwich, cloth sponge sandwich, flocking cloth, nylon cloth, TPU, PU leather, EVA, leather, artificial leather and other materials. At present, it is commonly used for single-layer paper card and blister packaging sealing welding, PVC double-sided blister packaging sealing welding and trimming, double-sided paper card clip blister packaging sealing heat sealing, mainly used for electronic products, hardware tools, daily necessities, gifts, lamps, sanitary ware, kitchenware, medical supplies and other product packaging sealing. Heat seal, weld and seal the product, and use high-frequency processing to shape the product. The hot-pressed product has no burrs, smooth edges, firm interfaces, waterproof, airtight, durable, and beautiful product appearance. The blister packaging product feels excellent, easy to hold, and high-end.

Equipment operation process:

The automatic turntable high-frequency heat sealing machine is a machine with the function of heat-sealing packaging welding and sealing. When working, the blister shell to be welded is transported to the bottom of the mold position through the automatic turntable. The head cylinder drives the upper mold to descend. After delayed preheating, heat sealing and shaping, and pressure holding, the head rises. At the same time, the operator puts the blister shell products to be welded in the lower mold at other positions of the turntable. The automatic material-retrieving manipulator device automatically removes the blister product mold that has completed heat sealing and welding, without manual material retrieval. The automatic turntable system automatically rotates a mold position to start the next operation cycle. The operator only needs to put the unheated pressed product into the lower mold position of the turntable. The 3-station turntable mold positions work in turn without stopping, and the work efficiency is extremely high. In production, the time of each process can be freely set according to the product specifications, generally 4-6 seconds for one operation process.

Machine advantages:

① The disc worktable rotates smoothly, the work station positioning is accurate, efficient and high-precision.

② The robot automatically takes materials, saving time and high efficiency. It is a good tool for factories and enterprises to save labor and improve efficiency.

③ The spark protection circuit is sensitive and effectively prevents sparks.

④ Automatic and manual modes can be freely selected for easy machine and mold adjustment.

⑤ Rectifier overload protection effectively protects the electron tube and mold from damage.

⑥ It usually takes 4-6 seconds to complete one mold. If one mold (2 pieces) is used, 600 to 1,000 pieces can be produced per hour, with extremely high production efficiency.

⑦ Safe operation, with automatic, manual, emergency stop and other operating button switches, which greatly improves the safety index and meets the requirements of mechanical engineering operation. The automatic turntable high-frequency heat sealing machine can be customized non-standard.

Application Industry:

Automatic turntable high-frequency heat sealing machine is used in medical supplies industry, plastics, plastic packaging industry, clothing embossing processing industry, auto parts industry, inflatable toy industry, household products industry, and various plastic products processing heat sealing and welding sealing such as: blister sealing, PVC plastic blister sealing, PVC blister welding, PVC plastic blister welding, battery packaging sealing, hardware tool sealing, PETG blister sealing, blister cardboard sealing, U disk packaging sealing, memory stick packaging sealing, PVC blister welding, high-frequency plastic welding, high-frequency plastic welding, high-frequency plastic sealing, double-sided blister sealing, PVC double-sided blister sealing, double-sided cardboard blister sealing, cardboard blister sealing, plastic plastic heat sealing, welding, etc.