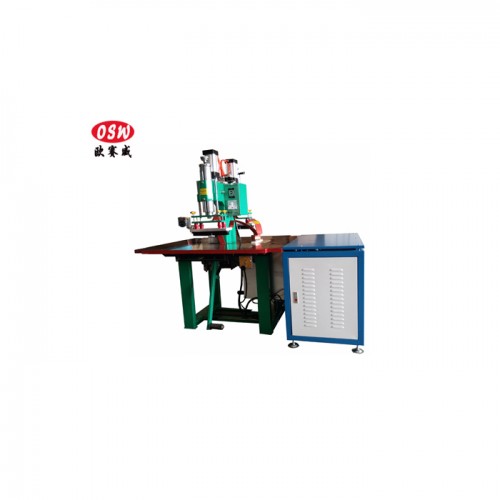

Double-head foot-operated high frequency machine

Detailed description:

【Product Features】 Double-headed pedal type. Easy to operate, uniform pressure. 40.68MHZ international standard oscillation frequency, high-frequency stable output

【Specifications】 5KW power. Please refer to the technical parameter table for details.

【Main Functions】 Dual-station pedal control, convenient and fast, special mechanical structure, can output 800kg pressure.

【Main Applications】 More suitable for cloth embossing, thin soft glue welding, inflatable toys, PVC trademark printing, blister packaging, etc. Suitable for workpieces that require greater pressure to achieve a more beautiful welding effect.

Machine features:

①Using vacuum electron tubes, the output power is stable and reliable.

②Highly sensitive spark overcurrent protection circuit. It can effectively cut off damage to the host due to high current output and suppress sparks.

③Equipped with high-frequency stabilizer and high-frequency shielding device to minimize high-frequency interference.

④Steplessly adjust the machine head stroke, the maximum pressure of the special mechanical pedal mechanism can reach 400KGS.

⑤ Four-angle horizontal adjustment, mold adjustment is simple and time-saving. Double guide rod structure, high precision, flexible operation; time preset, mechanical interlocking, machine head alternate working, lever toggle transmission pressurization, labor-saving, uniform pressure.

⑥Automatic over-current protection system increases the service life of vacuum tubes and protects molds.

Scope of application:

Blister Pack Inflatable Toy Raincoat Rain Gear

Bags, Stationery Stickers, Genuine Leather Embossed

Footwear trademarks, car seat fabric embossing, etc. Any plastic welding with PVC or P.VC content above 30%.

Technical parameters of double-head pedal high frequency machine:

Model | OS-5000T |

High frequency output Output Power | 5000W |

Input Power | 8KVA |

Power Voltage | 220V or 380V |

Oscillation | 27.12MHz |

Rectifier | Silicon Diode |

Way of pressure | Pneumatic |

Oscillation tube | 7T85RB |

SIize of disk | 350×700mm |

Gap ofeletr | 160mm |

Size of machine | 1720/1100/1500mm |

Machine move distance | 60mm |

Weight of machine | 320kg |

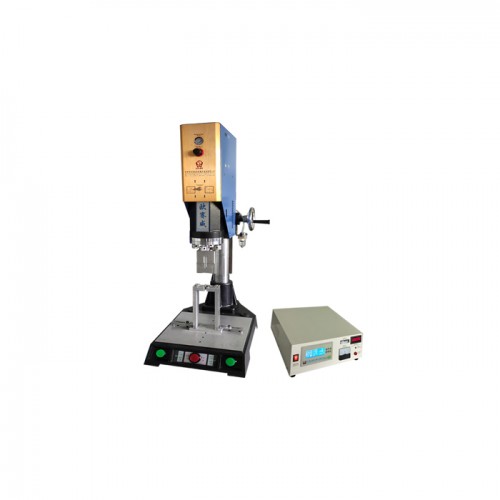

High frequency series: single-head push-disk high frequency machine, single-head turntable high frequency machine, double-head hydraulic high frequency machine, double-head pneumatic high frequency machine, double-head foot-operated high frequency machine, fully automatic high frequency synchronous fusing machine, high frequency metal speaker mesh embedding machine, non-standard high frequency machine, fully automatic plastic welding equipment, etc.

High frequency application range: High frequency plastic welding machine (also known as high frequency machine, heat sealing machine, high frequency) is the preferred equipment for plastic heat sealing. It uses high frequency electric field to make the internal molecules of plastic oscillate to generate heat energy to fuse various products. Mainly used for: various plastics mainly made of polyvinyl chloride (PVC), welding, hot stamping, etc. Blister packaging (including upper and lower double blister heat sealing and trimming, blister and cardboard heat sealing and trimming, etc.), automotive interior parts, cushions, trademarks, stationery, stickers, plastic covers, inflatable toys, footwear products, rain sails, umbrellas, raincoats, leather bags, speaker net speakers, brand names, water beds, sun visors, door panels, heat sealing processing of various packaging bags, portable soft bags, etc., various concave and convex switch patterns, letter pressing. It can also be hot stamped with a simple device.

High frequency uses: cardboard, blister welding and cutting, automobile, leather pads, door panel hand guards, sun visor welding and cutting, uppers, soles, welding and cutting, trademarks, watch straps, leather cases welding and cutting, paper cards and blister melting at the same time, metal speaker nets and plastic implantation, welding, etc.

High frequency service: one-year free warranty for the whole machine, lifelong maintenance, mold making and processing services.

Frequently asked questions by customers:

1. How come you see that other merchants are selling machines cheaper than yours?

Answer: The quality, function, style, power, frequency and price of machines are different. The price of machines with the same function in our company is at the middle and lower level. The goods are genuine and the service is in place. We sell quality and rely on quality. We provide free door-to-door installation, commissioning and warranty in Guangdong Province. We deliver related molds, welding heads, jigs and fixtures when purchasing machines. It is economical and practical. Welcome to compare and purchase.

2. What should I do if I don’t know how to use the equipment I bought in other provinces?

Answer: You can send people to our company for training and study. Our company provides free training on adjusting the machine, mold head, jig and welding head. It is simple and easy to learn. It is guaranteed to learn basic debugging molds within one hour. If you don’t want to come to our company to study, you can communicate by phone, WeChat, QQ, etc. There are also teaching materials videos on adjusting the machine and mold. They are all simple and easy to learn. Don’t worry about this. Please feel free to buy.

3. How is the warranty for equipment purchased in other provinces? How long is the warranty? What should I do if the equipment breaks down?

A: The free warranty period for all machines is unified as one year, with lifelong maintenance. The ultrasonic circuit mainly includes the main board, program board, capacitor board, and power board; the high-frequency core accessories are the electron tube, followed by the transformer, etc. If there is a fault, please remove it and send it back to us, and we will replace it free of charge. Our installation process has a strict installation process. The machines are aged tens of thousands of times and are inspected by a dedicated QC before leaving the factory. The failure rate is very low. Our factory has more than ten years of production technology and excellent quality. Please rest assured to buy.

4. How do I know that your machine can solder my product well?

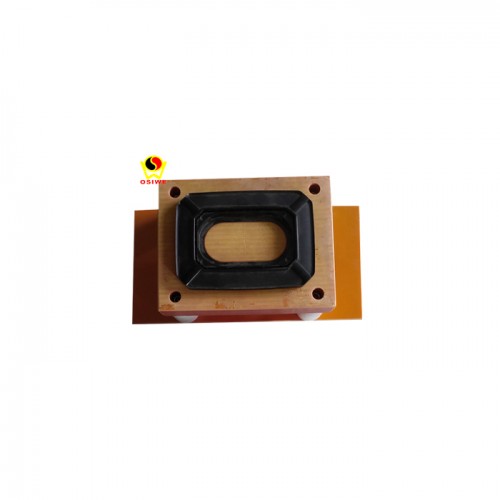

Answer: Our company has specially set up an ultrasonic mold manufacturing department and a high-frequency mold department. The general process of buying a machine is: send samples and product 3D drawings, we will help to make the mold, make a sample after the mold is made, send the sample to the customer, confirm that it is OK, and then send the machine (for small products, the mold can be installed first, and the customer can directly start production by plugging in the air source and power supply after receiving the machine). Our factory produces machines and related molds, and provides integrated services such as mold making, machine maintenance, and processing of supplied materials. We can solve the worries of customers. Please feel free to use our machines.

5. How do you ship goods from other provinces?

Answer: For goods from other provinces, we usually pack wooden boxes and then send them according to customer requirements.

We have customers all over the country (Beijing, Tianjin, Anhui, Henan, Hebei, Shanghai, Zhejiang, Hunan, Hubei, Guizhou, Sichuan, Jiangxi, Guangxi), and we have a mature process for sales services in other provinces.