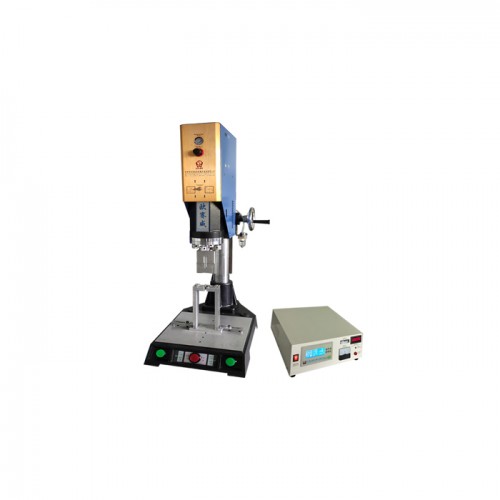

Intelligent ultrasonic machine, 15K ultrasonic plastic welding machine transmits ultrasonic waves to the weldment through the vibrator and the welding head. Due to the large acoustic resistance between the two weldments, local high temperature is generated, which melts the interface of the weldment. Under a certain pressure, the two weldments can achieve a fast, firm and beautiful welding effect.

Equipment Application:

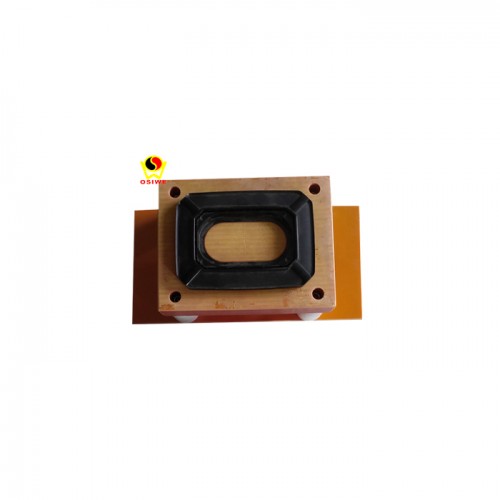

Electronics industry: mobile phone accessories, mobile phone cases, power boxes, chargers, mobile phone batteries, Bluetooth, USB connectors, computer accessories, U disks, laptop batteries, electronic digital products, GPS antenna anti-theft devices, electronic monitors, plastic baits, waterproof flashlights, and other plastic products for welding and welding.

Automobile industry: body plastic parts, car instruments, headlights and mirrors, sun visors, bumpers, water tanks, car accessories, etc. Stationery

and toys: folders, photo albums, folding boxes, pen caps, plastic toys, etc.

Medical industry, home appliance industry, non-woven clothing, office supplies, packaging industry, kitchen supplies, ABS and PC plastic materials that can be welded, etc.

After-sales service: 15K ultrasonic plastic welding machine has a one-year free warranty, lifelong maintenance, and integrated services of mold making and material processing.

Machine features:

1. IC precision control circuit, automatic overload protection system;

2. Digital welding parameter setting, intuitive and accurate;

3. Adopting Japanese circuit power mode, stable performance, strong output, automatic overload protection to safely protect the machine circuit and power board.

4. The transducer uses original Japanese imported NTK piezoelectric ceramic chips with strong power output.

5. Four-point balance adjustment, easy to adjust the welding head;

6. There is resonance when there is no load or no load, and there is no need to adjust the welding head frequency;

7. Round column, guide bearing, precision fine adjustment;

8. The machine body travel is easily adjusted by turbine rotation, which solves the adjustment drawbacks of conventional machines;

9. Aluminum alloy spoke rod, strong and stable sound waves;

10. We have our own welding mold workshop, using American aerospace 7075 aluminum alloy material, which is durable;

11. Adopting electronic components from Japan, the United States, Taiwan and other factories, with excellent and reliable performance.

12. Scope of application: Various injection molded parts and welded thermoplastic products, etc.

Warm reminder: Our factory has been producing machinery for more than 10 years and can solve various welding problems for customers. We can customize various non-standard machines, automated plastic welding equipment and molds according to customer product requirements. For specific details, please call us (same number for VX mobile phone).