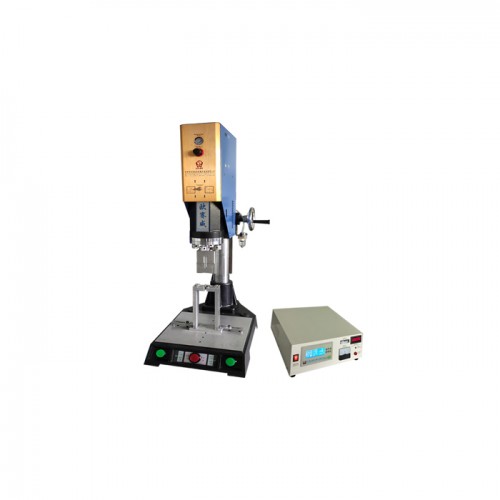

The new intelligent frequency control system of the automatic frequency tracking ultrasonic plastic welding machine eliminates the inconvenience of manual frequency adjustment, automatically detects sound wave overload, automatically adjusts the frequency band, and tracks the resonance point in real time. The machine runs more stably, the temperature of the vibration group remains low, and the temperature of the welding head rises and follows the frequency change. The machine automatically adjusts.

Abnormal automatic shutdown reduces product defective rate and prevents machine damage. Full Chinese interface operation, digital counter, multiple working states, manual, automatic, mode work.

Three intelligent protection functions to protect the machine:

1. Mold current is too high protection;

2. Frequency offset protection;

3.Total output is too large protection.

Precise time control settings:

No time difference, the maximum time is 9.999 seconds, and can reach 1ms increments (one thousandth of a second). Direct input fast time setting is faster than using the navigation key to add and subtract time settings.

Multi-level amplitude control, both large and small rubber parts can be perfectly welded, effectively reducing defective products such as penetration and burns.

4.3-inch touch screen display, clear parameters of each part, simple operation, convenient and flexible welding parameters. The counter can input the initial value for easy counting and memory.

Product specifications and models

The main technical parameters and features of the automatic frequency tracking ultrasonic plastic welding machine are as follows:

Model | OL-2015Z | OL-2018Z | OL-2020Z |

power | 1500W | 1800W | 2000W |

frequency | 20KHz | 20KHz | 20KHz |

Input voltage | 220V | 220V | 220V |

Input Power | 1.5KW | 1.9KW | 2.3KW |

Welding head travel | 80mm | 80mm | 80mm |

Output time | 0.01-9.9s | 0.01-9.9s | 0.01-9.9s |

Welding area | 150m/m φ | 170m/m φ | 190m/m φ |

Machine weight | 75kg | 78kg | 78k |

Machine features:

1. Automatic frequency tracking, using high-performance anti-interference microprocessor to achieve electronic control, all welding control parameters are managed by the microcomputer.

2. Intelligent frequency control system eliminates the inconvenience of manual frequency adjustment, automatically detects sound wave overload, automatically adjusts the frequency band, and tracks the resonance point in real time.

3. The machine runs more stably, the temperature of the vibration group remains low, the temperature of the welding head rises and follows the frequency change, and the machine automatically adjusts.

4. Strong and stable output, digital circuit intelligent chip control, German IGBT module, phase-shifted full-bridge, stable and strong output.

5. Easy to operate. After the welding head is replaced and firmly fixed, the machine will automatically detect and track the frequency of the new welding head. The machine will automatically stop if there is an abnormality, which can reduce the defective rate of products and prevent machine damage.

6. The transducer uses original Japanese imported NTK piezoelectric ceramic chips with strong power output.

7. Four-point balance adjustment, easy to adjust the welding head level;

8. The machine body travel is easily adjusted by turbine rotation, which solves the disadvantages of height adjustment of conventional machines;

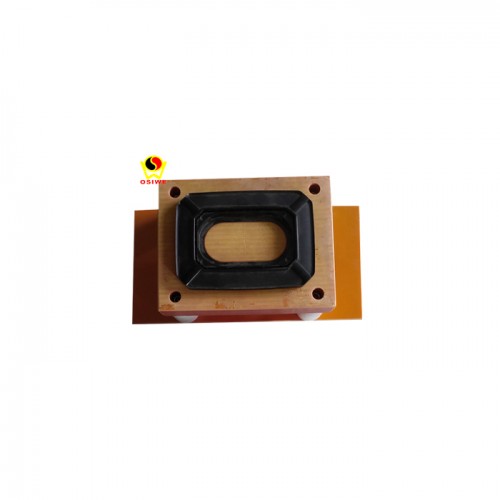

9. We have our own welding mold workshop, using American aerospace 7075 aluminum alloy material, which is durable;

Scope of application: various injection molded parts and welded thermoplastic products, etc.

Widely used:

Electronics industry: mobile phone accessories, mobile phone cases, power boxes, chargers, mobile phone batteries, Bluetooth, USB connectors, computer accessories, U disks, laptop batteries, electronic digital products, GPS antenna anti-theft devices, electronic monitors, plastic baits, waterproof flashlights, and other plastic products for welding and welding.

Automobile industry: body plastic parts, car instruments, headlights and mirrors, sun visors, bumpers, water tanks, car accessories, etc. Stationery

and toys: folders, photo albums, folding boxes, pen caps, plastic toys, etc.

Medical industry, home appliance industry, non-woven clothing, office supplies, packaging industry, kitchen supplies, ABS and PC plastic materials can be welded products, etc.

Service: one-year free warranty for the whole machine, lifelong maintenance, mold proofing, and integrated processing of incoming materials

. Warm reminder: Our factory has been producing machinery for more than 10 years and can solve various welding problems for customers. According to customer product requirements, various standard machines, non-standard machines, automated plastic welding equipment and supporting molds are customized. For specific details, please call us (WeChat and mobile phone numbers are the same).