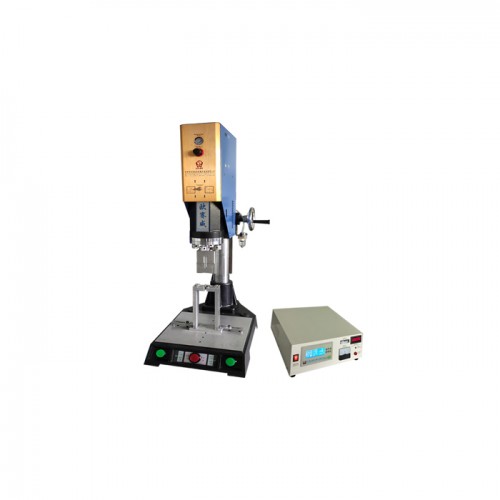

15K high power ultrasonic welding machine , 4200W ultrasonic welding machine , high power ultrasonic plastic welding machine , large workpiece plastic welding machine.

【Product Features】 Adopting the brand steel horn, super high power, large welding area.

【Specifications】 Power 4200W Frequency 15KHZ.

【Main Function】 Welding various hard plastic parts that are difficult to melt and relatively large.

【Main Application】 Mainly used for welding and welding of various plastic parts.

Technical parameters:

model | OL-1542 |

power | 4200W |

frequency | 15KHz |

Input Power | 5.5KW |

Input voltage | 220V |

Welding head travel | 80mm |

Output time | 0.01-6s or CNC 0.01-9.9s |

Welding area | 360m/m φ |

Machine weight | 300kg |

The high-power ultrasonic welding machine parameters can be set according to the requirements of the actual workpiece.

Scope of application:

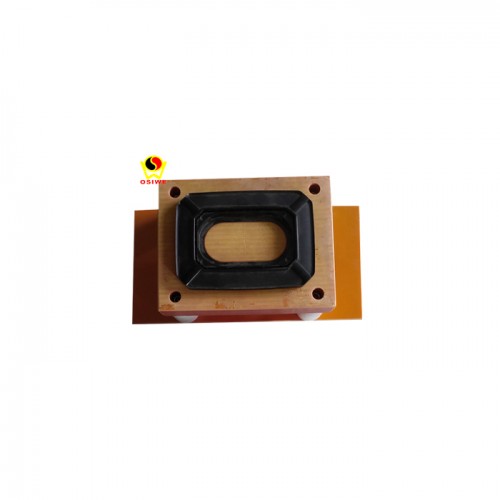

Electronics industry: mobile phone accessories, mobile phone cases, power boxes, chargers, mobile phone batteries, Bluetooth, USB connectors, computer accessories, U disks, laptop batteries, electronic digital products, GPS antenna anti-theft devices, electronic monitors, plastic baits, waterproof flashlights, and other plastic products for welding and welding.

Automobile industry: body plastic parts, car instruments, headlights and mirrors, sun visors, bumpers, water tanks, car accessories, etc. Stationery

and toys: folders, photo albums, folding boxes, pen caps, plastic toys, etc.

Medical industry, home appliance industry, non-woven clothing, office supplies, packaging industry, kitchen supplies, ABS and PC plastic materials that can be welded, etc.

Service: One-year free warranty for the whole high-power ultrasonic welding machine, lifelong maintenance, mold making and processing services.

Features of the whole machine:

IC precision control circuit, automatic overload protection system;

digital code precision control switch, 1/100 accurate setting;

four-point balance adjustment, easy to adjust the welding head;

The original NTK transducer (vibrator) has a stronger power output than its peers;

it resonates when unloaded or free of load, and there is no need to adjust the welding head frequency;

rectangular columns and cylinders are optional, with guide bearings and precise fine-tuning;

the body stroke is easily adjusted by turbine rotation, which solves the adjustment drawbacks of conventional machines;

the spoke rod is variable, and the sound wave is strong and stable;

we have our own welding mold workshop, using American aerospace 7075 and 6064 aluminum alloy materials, which are durable;

we use electronic components from Italy, Japan, the United States, South Korea, Germany and other factories, with excellent and reliable performance.

Recommendation and introduction: Integrated high-power model, suitable for welding products with high requirements on workpiece area;

automatic protective film device, which can be selected according to the surface requirements of the workpiece to be welded;

4200W high-power ultrasonic welding model, suitable for welding super-large workpieces in one welding.

High power ultrasonic welding machine, OL-1542 ultrasonic plastic welding machine , produced and sold directly by Shenzhen Ousaiwei Machinery Factory.