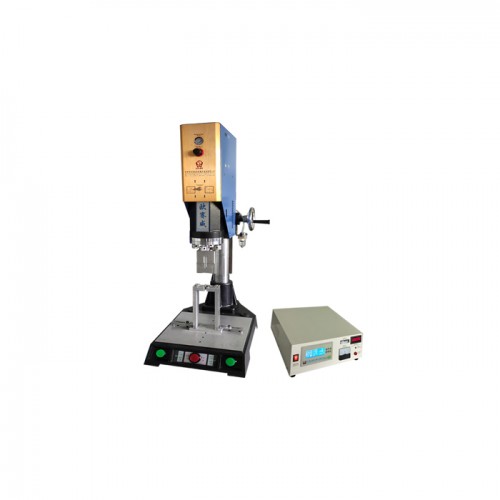

Ultrasonic rotary melting machine

Detailed Description

Function: Ultrasonic spin-melting plastic welding uses the heat generated by the friction between plastic workpieces to melt the contact surface of the plastic workpieces, and then relies on external pressure and drive to rotate and solidify the upper and lower workpieces into one. It uses imported motors and brake clutches, and runs smoothly and reliably. It uses imported time relays for control, and the parameter settings are intuitive and accurate. It has delay and solidification functions, high production efficiency, and low defective rate. It is suitable for round plastic workpieces that are not easy to weld with ultrasonic waves.

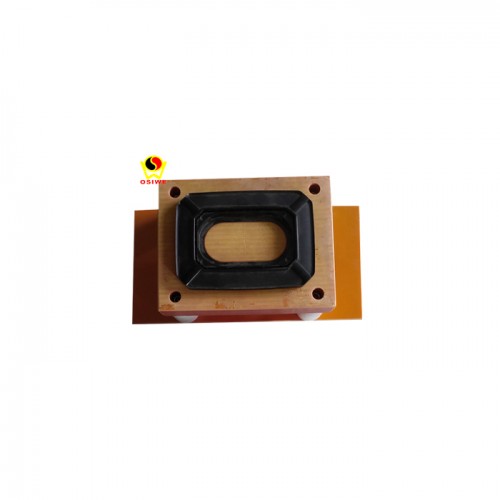

Product image:

Applicable: welding of oil filter, water filter, water spray joint, buoy, paint bucket, laundry trough, thermos, PP insulation cup, round objects.

Applicable materials: ABS, PC, PE, PP, PS and other plastic products

Technical Parameters

Voltage: 380V50HZ

Power: 2000W

Working stroke: 80MM

Welding time: 0-10S adjustable

Air pressure: 0.2-7Bar

Capacity: 1 time/0.1-3S

Net weight: 280KG

Dimensions: 650X870X1800

Ultrasonic rotary melting machine application scope:

Electronics industry: mobile phone accessories, mobile phone cases, power boxes, chargers, mobile phone batteries, Bluetooth, USB connectors, computer accessories, U disks, laptop batteries, electronic digital products, GPS antenna anti-theft devices, electronic monitors, plastic fish baits, waterproof flashlights, and other plastic products for welding and welding.

Automobile industry: car body plastic parts, car instruments, headlights and mirrors, sun visors, bumpers, water tanks, car accessories, etc. Stationery and

toys: folders, photo albums, folding boxes, pen caps, plastic toys, etc.

Medical industry, home appliance industry, non-woven clothing, office supplies, packaging industry, kitchen supplies, ABS and PC plastic materials that can be welded, etc.

Ultrasonic rotary melting machine service: one-year free warranty for the whole machine, lifelong maintenance, mold making and proofing, and processing of supplied materials.

Frequently asked questions by customers:

1. How come you see that other merchants are selling machines cheaper than yours?

Answer: The quality, function, style, power, frequency and price of machines are different. The price of machines with the same function in our company is at the middle and lower level. The goods are genuine and the service is in place. We sell quality and rely on quality. We provide free door-to-door installation, commissioning and warranty in Guangdong Province. We deliver related molds, welding heads, jigs and fixtures when purchasing machines. It is economical and practical. Welcome to compare and purchase.

2. What should I do if I don’t know how to use the equipment I bought in other provinces?

Answer: You can send people to our company for training and study. Our company provides free training on adjusting the machine, mold head, jig and welding head. It is simple and easy to learn. It is guaranteed to learn basic debugging molds within one hour. If you don’t want to come to our company to study, you can communicate by phone, WeChat, QQ, etc. There are also teaching materials videos on adjusting the machine and mold. They are all simple and easy to learn. Don’t worry about this. Please feel free to buy.

3. How is the warranty for equipment purchased in other provinces? How long is the warranty? What should I do if the equipment breaks down?

A: The free warranty period for all machines is unified as one year, with lifelong maintenance. The ultrasonic circuit mainly includes the main board, program board, capacitor board, and power board; the high-frequency core accessories are the electron tube, followed by the transformer, etc. If there is a fault, please remove it and send it back to us, and we will replace it free of charge. Our installation process has a strict installation process. The machines are aged tens of thousands of times and are inspected by a dedicated QC before leaving the factory. The failure rate is very low. Our factory has more than ten years of production technology and excellent quality. Please rest assured to buy.

4. How do I know that your machine can solder my product well?

Answer: Our company has specially set up an ultrasonic mold manufacturing department and a high-frequency mold department. The general process of buying a machine is: send samples and product 3D drawings, we will help to make the mold, make a sample after the mold is made, send the sample to the customer, confirm that it is OK, and then send the machine (for small products, the mold can be installed first, and the customer can directly start production by plugging in the air source and power supply after receiving the machine). Our factory produces machines and related molds, and provides integrated services such as mold making, machine maintenance, and processing of supplied materials. We can solve the worries of customers. Please feel free to use our machines.