PP waterproof welding machine high frequency induction machine series equipment: high frequency induction welding machine, high frequency induction heating machine, metal speaker mesh plastic welding machine, high frequency induction welding machine , high frequency metal speaker mesh embedding machine,high frequencyinduction heating machine, metalplastic weldingmachine, audio speaker mesh induction embedding machine, PP waterproof welding machine, high frequency inductionplastic weldingmachine, water tank welding machine, audio mesh plastic and metal parts welding machine,high frequencyinduction welding machine, external small industrial soda machine, to ensure thatthe high frequencyhigh frequencystably at a constant water temperature. 100% duty cycle design, 24 hours operation at maximum power. The equipment is easy to operate, just connect to the power supply and water to use.

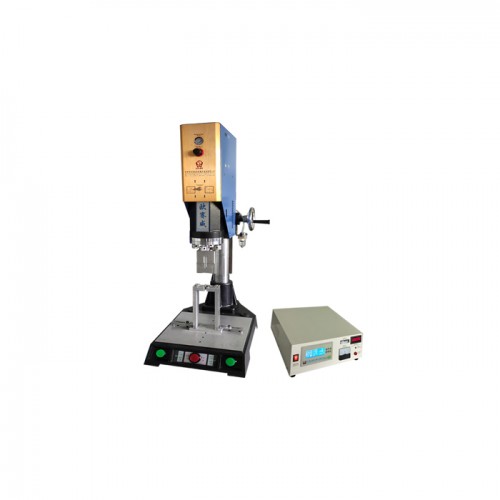

High- frequency induction power output can be freely set according to the size of the workpiece to meet the needs of implant welding of metals and plastics of different sizes. It uses crystal-type high-frequency induction heating technology based on the principle of electromagnetic induction to penetrate plastic products and instantly generate induction heating for the induction objects embedded in plastic products in a non-contact manner, so that the interface of the workpiece melts quickly and then fills the gap between the interfaces. It is equipped with a complete mechanical device to achieve perfect welding.

High-frequency induction PP waterproof welding machine is a high-frequency series equipment with high cost performance. This equipment can freely set the output high-frequency power according to the size of the workpiece to meet the needs of embedded welding of products of different sizes. It can also be designed as a single-station or multi-station equipment according to customer needs. It can be designed into a left and right automatic slide table type, a multi-station automatic turntable structure, easy to operate, simple, convenient, safe, efficient and energy-saving.

High frequency induction welding machine, PP waterproof welding machine high frequency induction coil can be freely disassembled and replaced easily.

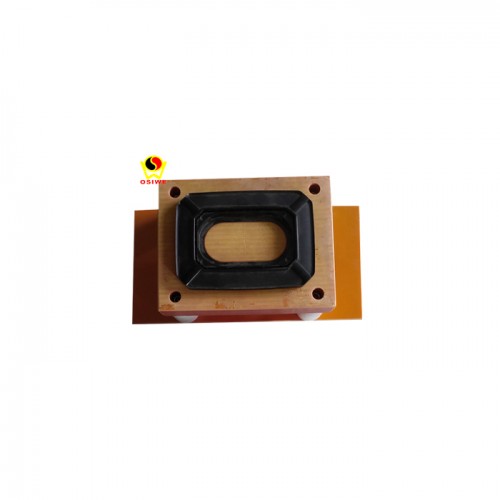

Especially suitable for speaker iron mesh welding, PP, PC, nylon, glass fiber, engineering plastic welding . Preheating and embedding or induction welding of metal parts, plastic parts, speaker mesh, etc. 100% watertight, airtight, high stability. For products with large and complex welding areas and high welding requirements, the welding effect is excellent. High-frequency and high-frequency induction heating, strong efficiency.

Automatic control type can adjust the current and time of the welding process to improve welding quality.

Application Industry:

Home appliance and audio industry (welding of metal speaker mesh and plastic);

PP waterproof welding machine for welding large or irregular plastic parts;

Scope of application:

Welding of metal and plastic products such as household electrical appliances, musical instruments, stationery, toys, and auto parts. For example, PP containers for kettles, PP containers for auto parts, speaker mesh implants for plastic speakers, metal mesh speakers, audio equipment, hardware products, plastic products, and metal and plastic implants for electronic products. PP containers for kettles and PP containers for auto parts can be welded by high frequency .After the speaker mesh embedding machine is embedded, it has good watertightness and airtightness. It can also be used to embed speaker metal mesh, metal to plastic embedding, etc.

High-frequency induction heating, also known as high-frequency induced heating, is a principle that uses high-frequency induction heating to heat metal parts , and then uses the pneumatic pressure of an embedding machine to embed the metal parts into the plastic. The embedded plastic parts are smooth, beautiful, firm and without any scratches.

Machine features:

1. Adopt the unique current conversion control technology of MOSFET and IGBT power tube.

2. High efficiency and energy saving, saving two-thirds of electricity compared with conventional high-frequency tube machines.

3. Lightweight and small in size, fast and uniform heating, easy and quick installation, convenient and safe operation, simple and easy maintenance, and the performance of the PP waterproof welding machine is efficient and stable.

4. The automatic control type can adjust the current and time of the welding process to improve the welding quality.

5. The induction coil can be freely disassembled and replaced easily.

6. The PP waterproof welding machine is particularly suitable for preheating and embedding or induction welding of metal and plastic parts.