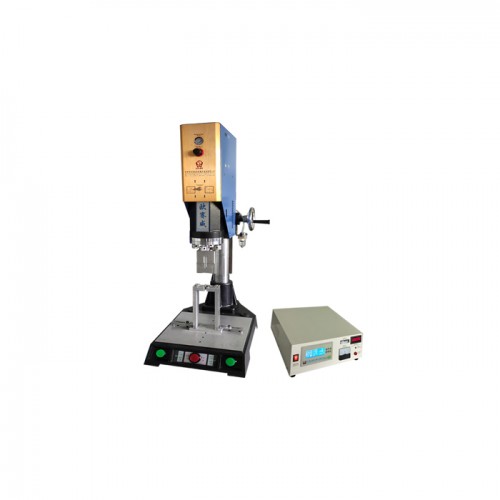

Detailed description of metal plastic welding machine :

The metal plastic welding machine, also known as the high-frequency induction machine, uses the crystal-type high-frequency induction heating technology that works on the principle of electromagnetic induction. It penetrates plastic products and instantly generates induction induction heating for the induction objects embedded in plastic products in a non-contact form, so that the interface of the workpiece melts quickly, and then fills the gap between the interfaces. It is equipped with a complete mechanical device to achieve perfect welding. The

metal plastic welding machine is a high-frequency equipment with high cost performance. This equipment can freely set the output high-frequency power according to the size of the workpiece to meet the needs of embedded welding of products of different sizes. It can also be designed as a single-station or multi-station equipment according to customer needs. It can be designed into a left and right automatic sliding table type, a multi-station automatic turntable type structure, which is easy to operate, simple, convenient and safe, and has high work efficiency.

The induction coil of the metal plastic welding machine can be freely disassembled and replaced.

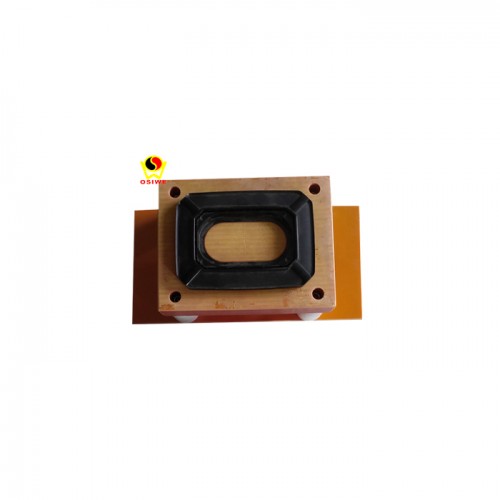

It is especially suitable for speaker iron mesh welding, pp, PC, nylon, glass fiber, and engineering plastic welding. Preheating and embedding or induction welding of metal parts, plastic parts, speaker mesh, etc. is 100% watertight, airtight, and has high stability. For products with large and complex welding areas and high welding requirements, the welding effect is excellent. High frequency and high frequency induction heating, strong performance.

Automatic control type can adjust the current and time of welding process to improve welding quality.

Machine Features

1. Adopt the unique current conversion control technology of MOSFET and IGBT power tube.

2. High efficiency and energy saving, saving two-thirds of electricity compared with conventional high-frequency tube machines.

3. Lightweight and small in size, fast and uniform heating, easy and quick installation, convenient and safe operation, simple and easy maintenance, efficient and stable performance.

4. Automatic control type can adjust the current and time of the welding process to improve the welding quality.

5. The induction coil can be freely disassembled and replaced easily.

6. Especially suitable for preheating and embedding or induction welding of metal and plastic parts.

Application Industry

Home appliance and audio industry (welding of metal speaker mesh and plastic);

Welding of large or irregular plastic parts;

Technical parameters:

Specifications model | OW-1500 | OW-2500 |

Biggest oscillatory power Maximum oscillation power | 15KW | 25KW |

Largest welding perimeter Maximum welding circumference | 950mm | 1400mm |

Input voltage Using Power | AC220V 50/60HZ | AC380V 50/60HZ |

Frequency Oscillation frequency | 30-80KHZ | 30-80KHZ |

Weld period time Welding time | 0.1-9.9S | 0.1-9.9S |

Cooling system Cooling system | Water cooling ≥0.2Mpa 2-5L/min | Water cooling ≥0.2Mpa 2-5L/min |

Air supply Air pressure range | 0-1Mpa | 0-1Mpa |

Net weight net weight | 150kg | 165kg |

Metal plastic welding machine high frequency induction machine , high frequency induction machine, PP material waterproof welding machine

Application industries:

Home appliance and audio industry (welding of metal speaker mesh and plastic); welding of large or irregular plastic parts;

1. Packaging industry:

With the rapid development of the packaging industry, high-frequency packaging is increasingly used in this field. Such as blister sealing, PVC plastic blister sealing, PVC blister welding, PVC plastic blister welding, battery blister hanging card packaging sealing, hardware tool sealing, PETG blister sealing, blister cardboard sealing, U disk hanging card blister packaging sealing, memory stick hanging card blister packaging sealing, PVC blister blister welding, high-frequency plastic welding, high-frequency plastic welding, high-frequency plastic sealing, double-sided blister sealing, PVC double-sided blister sealing, double-sided cardboard blister sealing, cardboard blister sealing, plastic plastic heat sealing welding, paper card + blister simultaneous fusing, light industry, food, beverage, candy, cultural supplies, craft gifts, hardware tools, daily necessities, chemical products, various packaging bags, hot water bottles, soft handbags, etc., including upper and lower blister heat sealing and trimming, blister and cardboard heat sealing and trimming, welding packaging electronics and other products.

2. Garment processing industry:

High-frequency synchronous fusing and hot pressing utilize the processed PVC, TPU, EVA, PETG, etc. and the mixture containing 10% PVC to melt instantly in the electromagnetic field and add a certain pressure to achieve the purpose of complete melting. It can also be applied to the processing of leather materials, cotton cloth and other PVC mixed materials. Leather, cloth, footwear, raincoat, trademark, rain sail, umbrella, leather bag, upper, hand bag, sole, welding and cutting, famous brand, various fabrics, leather products embossing such as: leather embossing, artificial leather embossing, polar fleece embossing, PVC leather embossing, badge, shoe and hat heat embossing, clothing embossing, leather embossing, hat embossing, silicone embossing, embossing of concave and convex molds and other embossing machine equipment. Leather case welding and cutting of various concave and convex patterns, pressing of letters and words, etc., can also be hot stamped with simple devices. The most commonly used material for life jackets is PU, and a few use PVC and PU. This is because TPU material molecules have better tension resistance and can withstand much better pressure than PVC and PU. Using TPU to produce life jackets greatly increases the safety factor of life jackets, the quality is more guaranteed, and the sales market is more promising. Therefore, TPU is a more common material used to produce technical life jackets.

3. Automobile industry:

heat-sealing and welding of various plastic materials, such as carpet embossing, soft film ceiling welding, mold structure welding, PVC canvas heat-sealing, PVC rolling door welding, PVC door mat welding, PVC spinneret floor mat embossing, PVC tent welding, screen heat-sealing, PVC projection cloth welding, industrial belt welding, industrial belt skirt welding and other plastic welding, such as: automotive interior parts, seat cushions, sun visors, door panels, leather pads, door panel hand guards, sun visor welding and cutting, especially focusing on meeting customer needs and designing and constructing.

4. Toys and daily necessities industry:

Stationery, stickers, plastic covers, inflatable toys, water beds, watch straps, clocks, electronics, toys, inflatable toys, cardboard hardware, gifts, CD bags, packaging bags, eyeglass boxes, photo albums, photo albums, business card books, notepads, electronic products, tools, sports goods heat sealing, battery blister packaging sealing, handicrafts, lock heat sealing and welding and others.

Equipment service: one-year free warranty for the whole machine, lifelong maintenance, mold making and material processing integrated service.