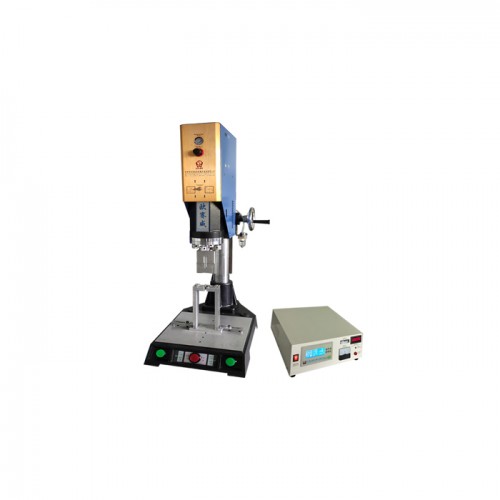

Multifunctional small riveting point hot press machine (also known as small multifunctional hot melt machine ), plastic column hot melt machine, plastic hot melt hot pressure riveting welding, metal nut implantation plastic column, small constant temperature riveting point hot press machine, plastic column riveting machine, hot melt nut implantation machine, small plastic column riveting multifunctional hot melt machine , pneumatic hot pressing, odorless, environmentally friendly and energy-saving.

Simple four-post multi-functionSmall riveting point hot press, small machine, fully functional, easy to move, with built-in safety grating to protect the palm, infrared device is sensitive to response, ensuring the safety of the operator and zero injury, double buttons on both sides of the two-handed operation can avoid accidental injury during one-handed operation, double protection is safer and more reliable!

Product Details:

The multifunctional small riveting point hot press machine on the four-column table adopts a double-headed solenoid valve. The cylinder of the double-headed solenoid valve has the function of pausing at any position. It is equipped with the electrical circuit of the multifunctional hot melt machine, and can be controlled manually and automatically. Two working modes can be selected:

1. Pause during the pressing process, suitable for preheating and embedding plastic columns, nuts, etc.

2. The rising process pauses, which is suitable for products that need to be cooled and pressurized after hot pressing.

3. There are two control modes: manual and automatic. The manual mode is convenient for mold installation and correction, and machine debugging; after debugging, the automatic mode can produce smoothly.

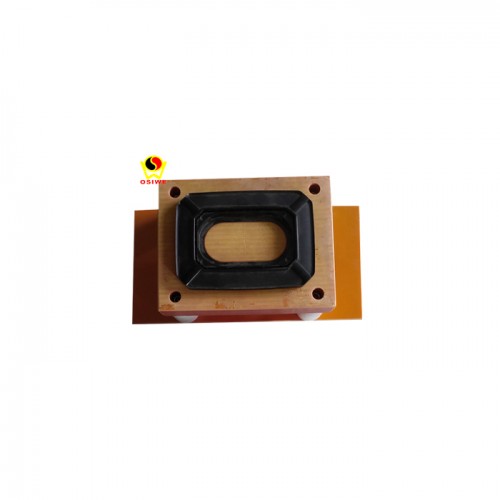

Small riveting point heat pressSuitable for plastic column welding, fan hot welding, nut implantation welding plastic column, metal nut implantation, plastic welding, copper nails, riveting molding.

Technical parameters:

model | OR-2012J |

Heating power | 1200W |

Input voltage | 220V |

Hot melt area | 200*120mm |

Melting temperature | 0-400℃ (adjustable) |

Welding time/delay time | 0.1-999 s (adjustable) |

Air pressure | 0-10KG (adjustable) |

Up and down clearance | 230mm |

Work surface | 380mm |

Machine size | L320*W380*H900mm |

Machine weight | 30kg |

Machine advantages:

1. Quantity thermostat: accurate temperature and small error;

2. Production output counting function;

3. The cylinder can move up and down in the mold adjustment state;

4. Cylinder descending speed adjustment function in working state;

5. Safety protection device: The operator must use both hands to start the switch of the machine to operate it. The small riveting point hot press is also equipped with a safety grating device for double protection.

Machine features:

1. The frame is made of aluminum, light and easy to move.

2. The whole machine has beautiful appearance, small desktop footprint, high production efficiency, and multifunctional built-in infrared protection device.

3. Two-hand button start improves the safety of practical operation.

4. Pneumatic components are flexible and accurate, with advantages such as adjustable buffer, low up and down speed and noise.

5. All hot melt products do not require the addition of any solvents, adhesives or other auxiliary products.

6. The equipment has a simple structure, stable performance, minimal maintenance, and the working height can be adjusted according to the size of the product or mold.

7. All accessories are imported from Taiwan, Japan, South Korea, etc. with reliable quality.

8. The double-headed solenoid valve has the function of pausing at any position. The pause during the downward pressing process is suitable for preheating and embedding of nuts; the pause during the upward pressing process is suitable for products that need to be cooled and pressure maintained after hot pressing.

The hot melt machine has a movable mold lock. To replace the upper and lower molds, you only need to loosen the screws and tighten them. The machine shape, size, and mold can be customized. The pneumatic hot melt machine needs to be equipped with an air compressor (air compressor). Only products and 3D drawings can be provided. Osaiwei can customize the mold production and proofing.

Scope of application:

Small riveting point hot press machine is used for welding plastic columns, riveting points, implanting nuts into plastic columns, hot pressing and welding plastic parts, hot riveting of hardware and electronic components, etc.

Our factory can customize various non-standard machines, riveting machines, metal embedding machines, and automated plastic welding equipment according to customer product requirements.