Product Name: Bottom Filler

Underfill solutions

Industry introduction: With the development trend of miniaturization, portability and diversified functions of electronic products, bottom filling has become a necessary process to improve the reliability of electronic products. For CSP, BGA and POP, bottom filling improves their impact resistance; for FLIP CHIP, because its thermal expansion coefficient (CTE) is inconsistent and thermal stress is generated, resulting in solder ball failure, bottom filling improves its ability to resist thermal stress.

Recommended curing conditions

Curing at 130℃ for 8min Curing at 120℃ for 15min The curing speed depends on the heating efficiency of the heating equipment, the thickness of the heated PCB board and the size of the chip. The curing temperature and curing time should be properly adjusted according to the heating equipment and the bonded object.

Instructions for use

It can be used only after it returns to room temperature. Please do not open the package before it returns to room temperature.

It can be filled directly at room temperature. If you need to speed up the filling speed, the PCB board must be preheated. The recommended preheating temperature is below 90℃. It is recommended to use "I" or "L" shape glue. When using "I" glue, the glue length is 80% of the chip side length. The glue speed is 2.5-12.7mm/s. The unused glue must be sealed and then stored in a -20℃ refrigerator. Each package of products can be used 2-3 times after warming up. It is not recommended to use it multiple times after warming up.

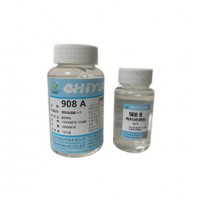

product name | Chemical Type | main feature | Exterior | Viscosity | halogen | Recommended curing conditions | Shelf life |

CYA1003 | Epoxy | Black matte | Black liquid | 4000 | <900ppm | 4min@120℃ | 6 months |

CY8113L | Epoxy | 100℃ matte black, 120℃ glossy black | Black liquid | 3500 | <700ppm | 10min | 6 months |

CY1208L | Epoxy | Fast curing, easy maintenance | Light yellow liquid | 1000 | <700ppm | 20min@80℃ | 6 months |

CY8116 | Epoxy | Fast penetration, easy maintenance, glossy black | Black liquid | 700 | <900ppm | 6min | 6 months |

CYA3001 | Modified thermoplastic polyurethane | Easy to maintain, glossy black | White/black solid | 12000 | <900ppm | Can be furnaced with SMT solder paste | 6 months |

CYA3001 solid underfill glue is a special modified thermoplastic polyurethane material with excellent toughness, good insulation performance, and strong resistance to high and low temperatures. It can be cured in the same furnace as solder paste to reduce the process and improve efficiency. | |||||||

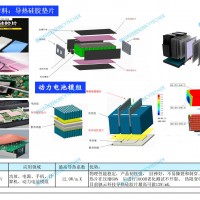

Application Areas