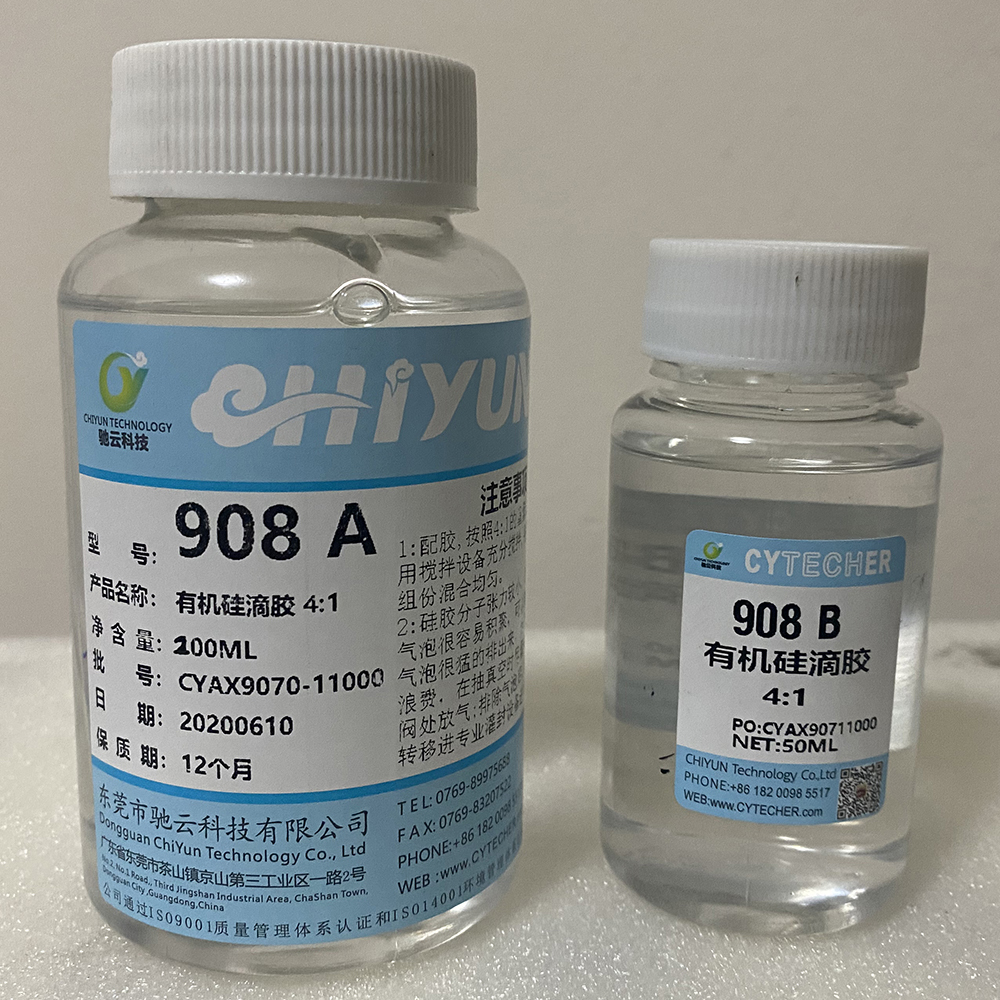

Product name: Silicone glue

Product Usage:

The product has excellent performance in combination with PCB board. The product has very good molding characteristics and can form a certain height on the 3528 light strip. It is mainly used for glue dripping on bare boards of LED soft light strips, and can also be used for glue dripping on half-tube LED soft light strips.

Operation Notes:

1. Prepare the glue, mix according to the weight ratio of 4:1, and stir it thoroughly with a stirring device (make sure the two components are mixed evenly). Note: the stirring rod and container cannot touch other glue!

2. Vacuum. Since the molecular tension of silicone is small, bubbles inside are easily accumulated when vacuuming, and a large number of bubbles can be seen being discharged violently. So in order to avoid the waste of glue, try to deflate the air at the vent valve as many times as possible when vacuuming.

3. After eliminating the bubbles, the glue can be transferred to the professional potting equipment for drip irrigation.

4. After the glue is dripped, leave it until the glue is completely cured before proceeding to the next process.

5. Glue application environment: Organic silica gel is cured at room temperature, mainly based on temperature and humidity. That is, the higher the temperature and the greater the humidity, the faster the glue cures, and vice versa. It is generally required that the temperature of the construction workshop be controlled between 25-30 degrees and the humidity be controlled between 65-70%.

Storage and packaging:

The product should be stored in a cool and dry place, 25 kg/set, and the lids of packaging barrels A and B should be sealed and stored immediately after opening.

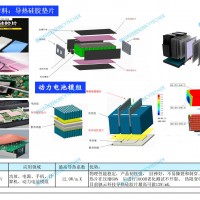

Application Areas