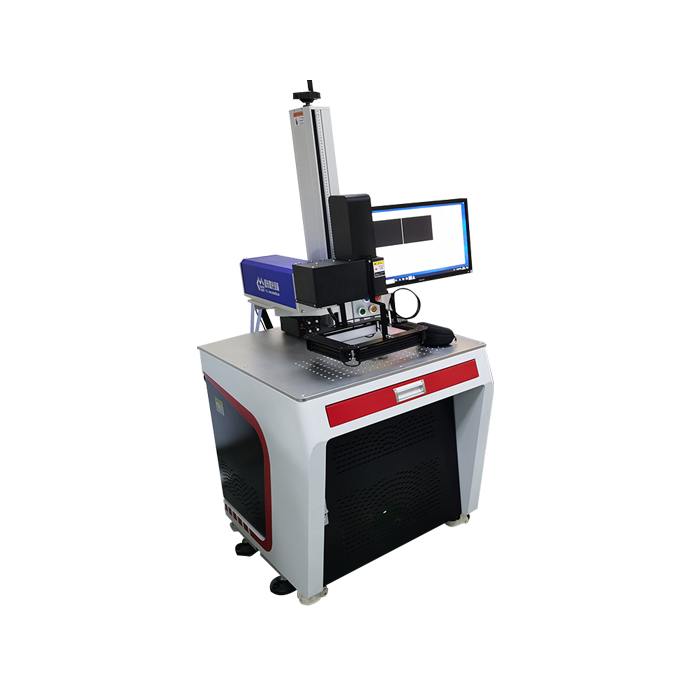

Product name: UV marking machine visual software installation

CCD visual laser marking machine principle:

This technology uses the principle of visual positioning. First, the product template is made and saved as a standard template. When processing, the product is photographed and compared and positioned by the computer. After adjustment, the product can be processed accurately. The shape of the processed product can be round, square, or irregular. This process is particularly suitable for small products, and can eliminate the need for positioning trays and fixing fixtures, greatly saving the laser marking processing cycle.

The new generation of laser machines equipped with this CCD vision system have three major advantages over traditional laser marking machines .

First of all, small-sized products are no longer a pain for laser marking or welding. The addition of vision makes "small" become "big", and the accuracy problem that traditional marking machines cannot control is solved here. Flying fiber laser marking machine

Second, the accuracy of the fixture is no longer the controller of the marking accuracy. The precise positioning of vision has liberated the precision of the fixture. At this time, the marking accuracy has nothing to do with the fixture.

Third, the angle and position of the product are no longer restricted. Just put the product within the light output range of the laser airport mirror, and there are no other requirements.