Product Introduction

CY913A high-strength modified silane sealant is a one-component moisture-curing modified silane sealant with good sealing performance and cohesive force. It is non-corrosive and non-polluting to the substrate and the environment. It has good bonding properties to a variety of materials such as metals, galvanized sheets, and stainless steel.

product features

● Environmentally friendly, high modulus, low viscosity. ● Fast surface drying, can be quickly positioned. ● Good weather resistance, durability, and earthquake resistance.

Main uses: Used for bonding the reinforcement of automobile windshields, elevators, and anti-theft doors; bonding and sealing of sheet metal materials such as galvanized sheets and stainless steel

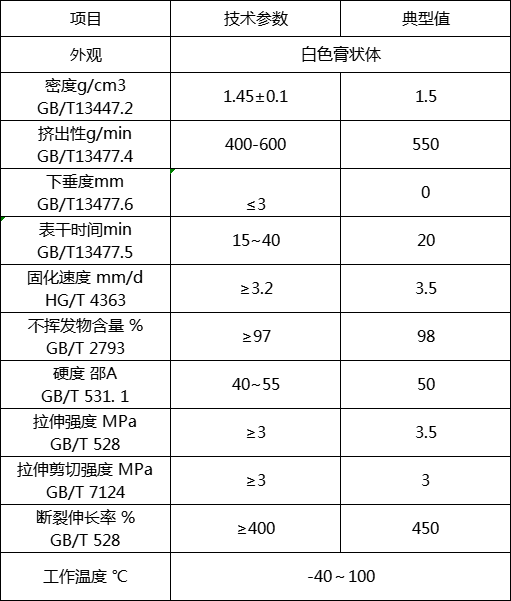

Technical Parameters

Instructions

● In order to ensure the bonding effect and compatibility between the product and the substrate, tests should be carried out on the actual substrate and environment in advance.

● The surface of the substrate to be bonded must be clean and dry, free of dust, oil and water stains.

Failure to do so may result in adhesive failure.

● Ambient temperature and humidity have a great influence on the surface drying and curing of sealant. The recommended construction environment temperature is 5~35℃ and humidity is 5~35℃.

When the temperature is below 5°C, it is recommended to place the product in a 30-40°C environment for heating.

1h before use (heating time cannot exceed 3h).

● The sealed joints can be smoothed with a scraper or hard foam strip, and some details can be smoothed with soap.

Water smooth.

● Before painting, you need to do a compatibility test. You can only paint after the surface is dry. You can only expose it to the baking temperature after it is completely cured.

Otherwise, bubbles will form. Pay attention to the thickness and hardness of the coating. Paint brittleness will reduce the elasticity of the glue and cause cracking of the paint layer.

● For construction methods, please refer to the construction instructions or consult our technical staff.

store

When CY913A is in its original packaging and stored in a cool, dry place below 27°C, the validity period of the sealant is: 9 months for 300ML/600ML aluminum cylinders and soft packs, and 6 months for iron barrels (calculated from the date of production).